THE FIRST

MECALAC 1000-L

ZERO EMISSION

LOADER

Mecalac swing loaders are compact, versatile, comfortable, safe, and highly powerful. Their innovative swing system and increased efficiency have been crucial for maintaining long-term market leadership in the swing loader sector, which they continue to expand.

Leading in autonomy, stability, mobility, and space management, the new electrified eS1000 Swing Loader allows operators to fully utilize the unique features of the machine. It operates with zero emissions and minimal noise pollution.

AUTONOMY

Less moves and more autonomy

The Swing Loader architecture is designed for efficiency, resulting in reduced movement and, consequently, shorter cycle times. This design leads to lower noise levels, decreased visual disturbances, minimized maintenance needs, and reduced accident risks, all while having a lesser impact on the environment.

While the diesel versions of the Swing Loader minimize fuel consumption through this efficient motion, the electric eS1000 model takes energy efficiency a step further. It consumes only the necessary amount of energy for the specific job site operation and optimizes battery use to provide an impressive 8 hours of autonomy.

STABILITY

Proven stability

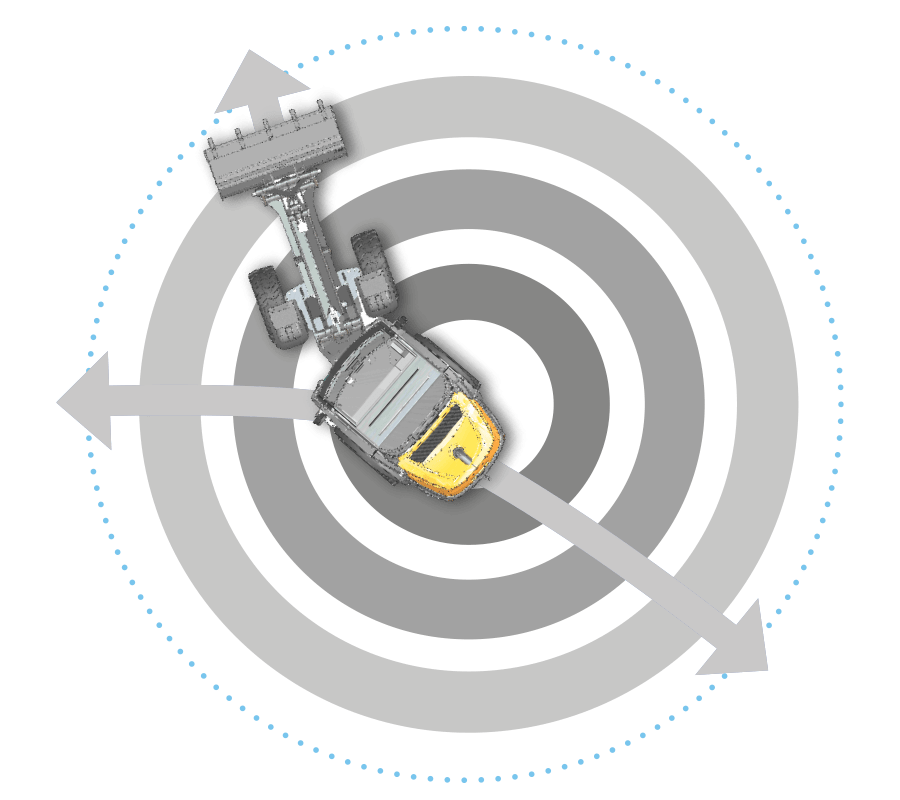

When the bucket at the front is lifted and the rear axle is locked, it can be rotated 180° without losing stability. This exceptional stability in all positions and on various terrains allows the Swing Loader to significantly improve logistics at construction sites.

No matter the situation, it maintains its balance whether moving on-site, between sites, or during different work stages. It also retains its mobility, effortlessly and reliably overcoming any obstacles in its path.

ARTICULATED LOADER

SWING LOADER

space

management

Mecalac Swing: Immediate Efficiency

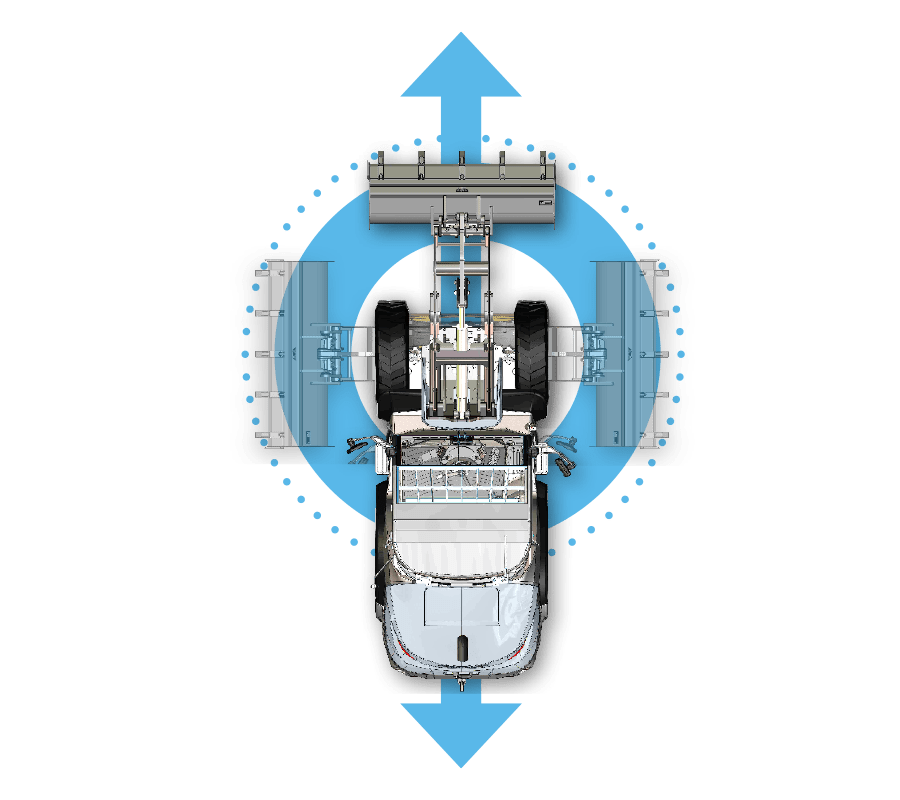

Urban construction sites and areas with limited space and time are ideal environments for compact wheel loaders. The small turning radius of our swing loaders allows for exceptional manoeuvrability. Additionally, efficiency is influenced by loading and unloading cycles, as a significant portion of conventional loaders’ cycle times is spent on time-consuming manoeuvres.

The innovative Mecalac Swing Loader concept was developed to enhance operational efficiency by minimizing non-value-added manoeuvres. Instead of relocating the entire machine, the boom can swing to perform tasks more effectively.

ARTICULATED LOADER

SWING LOADER

Specifications

| Total operating weight | 7085 kg (15,620 lbs) |

| Rated storage capacity | 75 kWh |

| Power supply | 32A 380V three phase (22kW) |

| Battery runtime | 8 hrs |

| Overall width | 1990 mm (6’6’’) |

| Tipping load (standard bucket, straight) | 4300 kg (9,480 lbs) |

| Bucket volumes | 0,95 m3 – 0,85 m3 – 1,20 m3 – 1,50 m3 (1,24 yd3 – 1,11 yd3 – 1,57 yd3 – 1,96 yd3) |

| Standard bucket volume | 1 m3 (1.3 yd3) |

| Boom type | Swing boom |