SWING LOADERS

The AS900tele is a telescopic swing loader that has a bucket capacity ranging from 0.7 to 1.2 m³. It comes equipped with a pallet fork and boasts a maximum lifting height of 4.72 m, a maximum outreach of 3.50 m, and a maximum carrying capacity of 2,270 kg when using the forks. The machine features powerful auxiliary hydraulics, allowing it to operate various attachments such as a mower, road sweeper, earth auger, and grab bucket. Additionally, there is an option to install an overload alarm system for added safety.

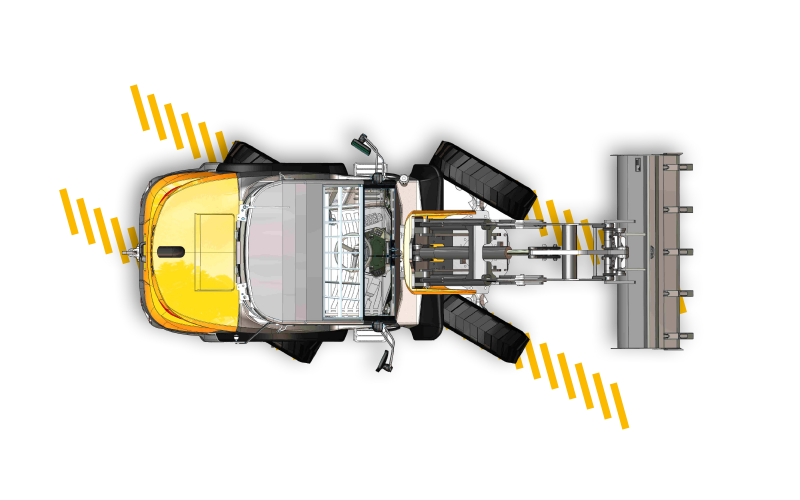

Swing Concept

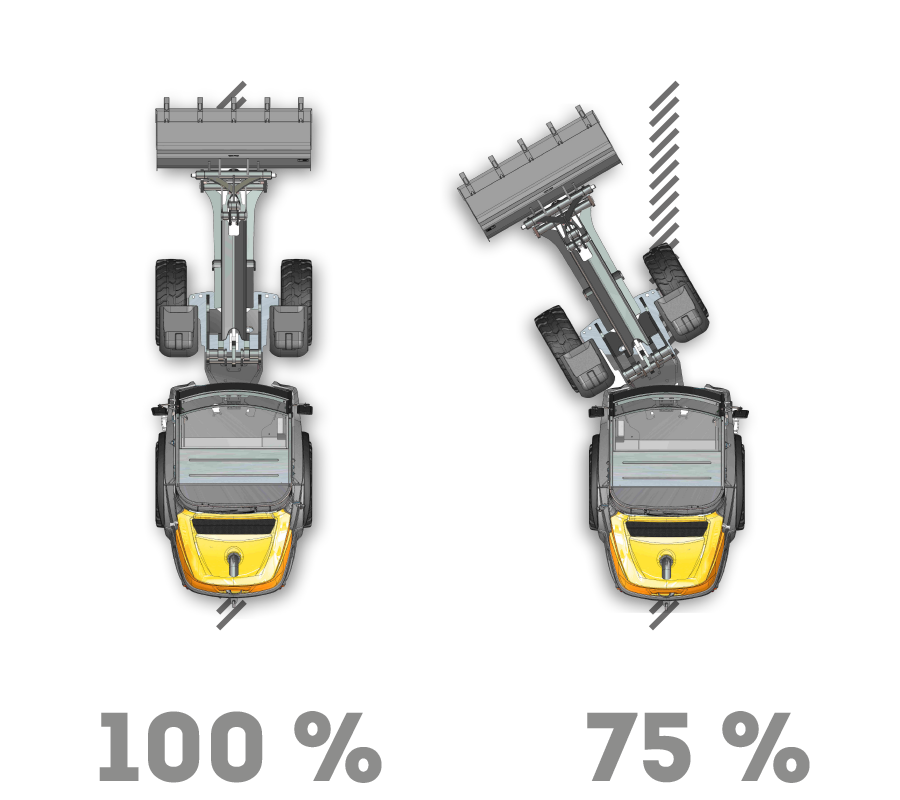

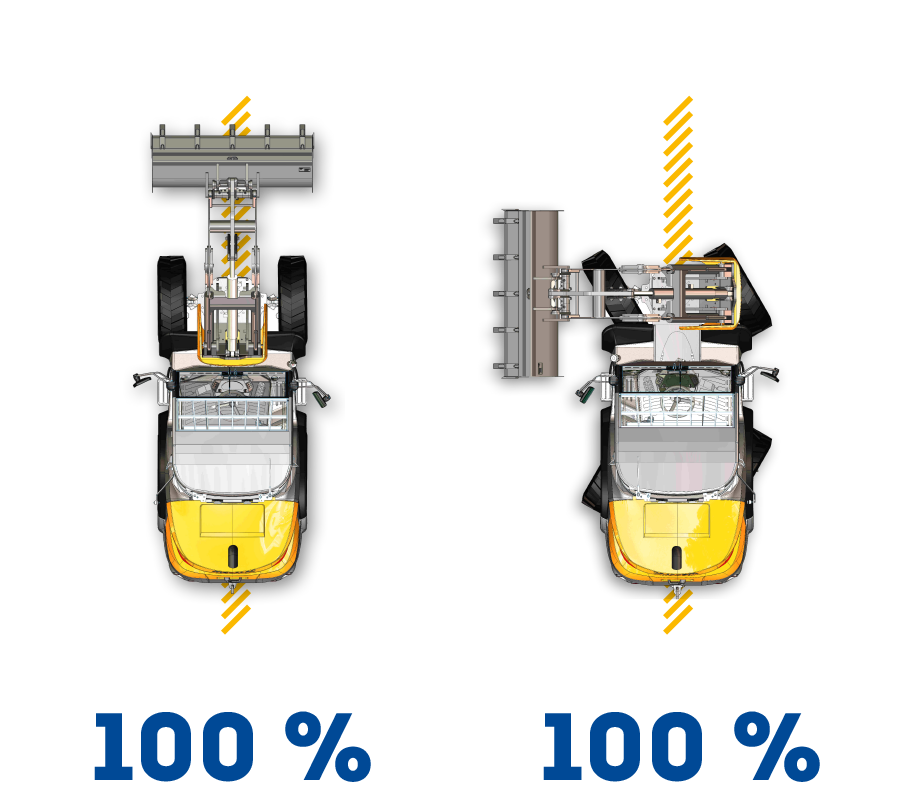

Stability

100% faster than any small excavator

Proven stability

The stability of this machine is completely assured. When the rear axle is locked, any load lifted by the front bucket can be rotated 180° without losing steadiness. Thanks to its remarkable stability on all terrains and in various positions, the Swing Loader significantly improves logistics at construction sites. No matter the circumstances, it maintains its equilibrium while moving on site, between sites, or during different work stages. It combines mobility with the ability to overcome obstacles effortlessly. Additionally, its small turning radius provides a high degree of manoeuvrability, even in the most confined spaces.

ARTICULATED LOADER

STABILITY

SWING LOADER

STABILITY

Swing Concept

Mobility

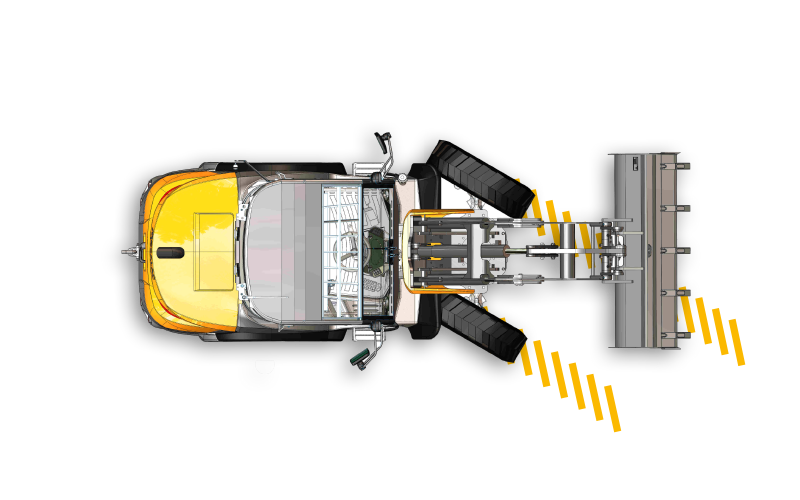

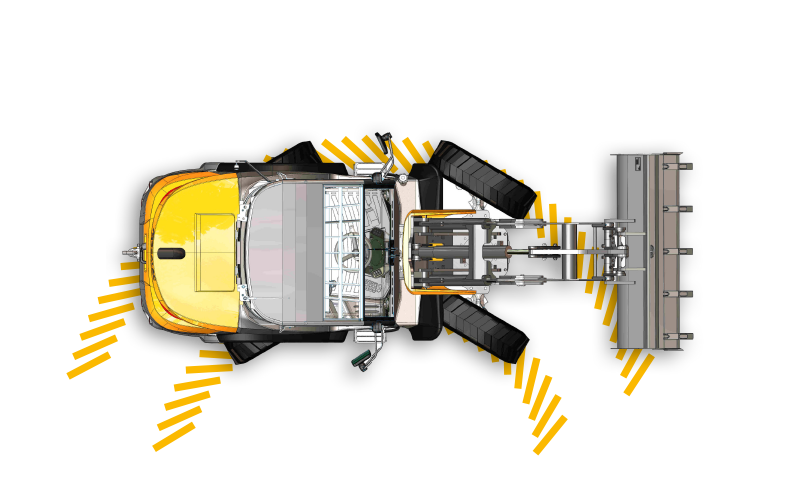

Three steering modes

Construction sites frequently face challenges such as congestion, limited workspace, and difficult ground conditions. This machine is designed with a one-piece frame and offers three standard steering modes: two-wheel steering, four-wheel steering, and crab steering. This design ensures exceptional mobility.

2-WHEEL

STEERING

4-WHEEL

STEERING

4-WHEEL

CRAB STEERING

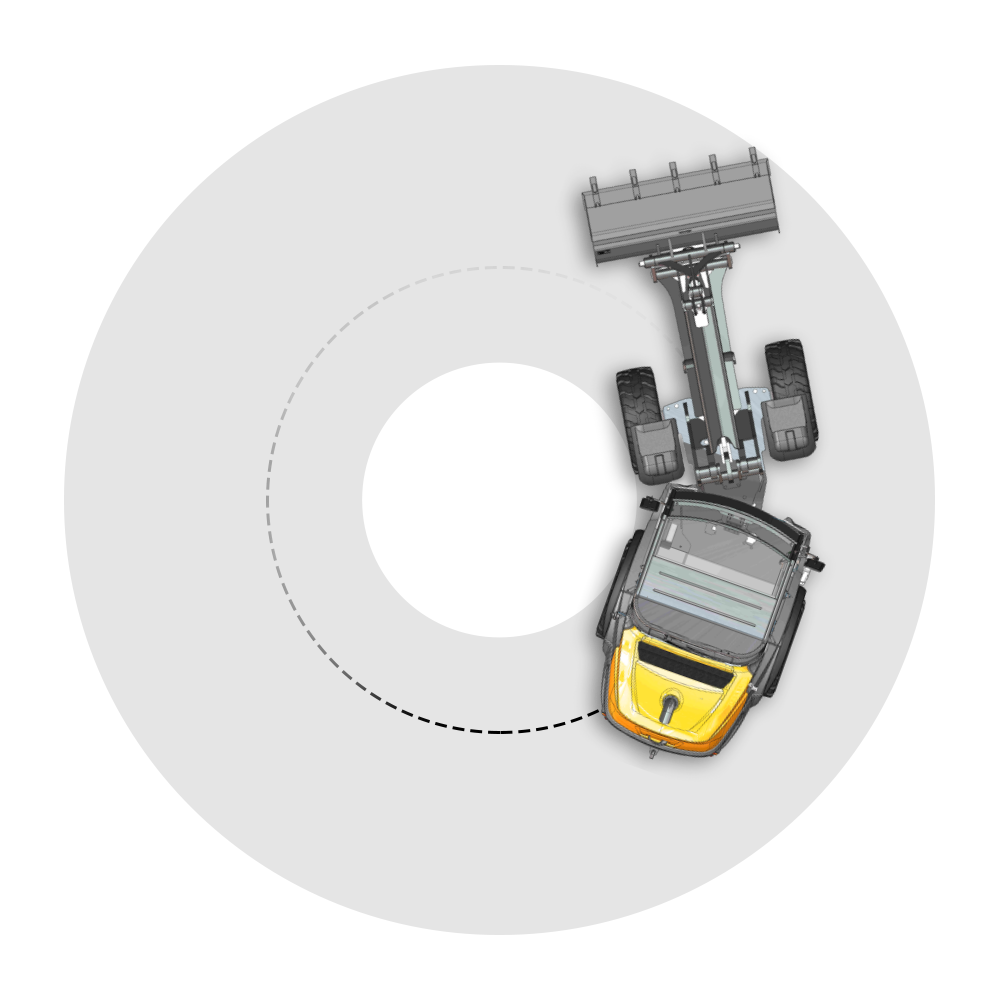

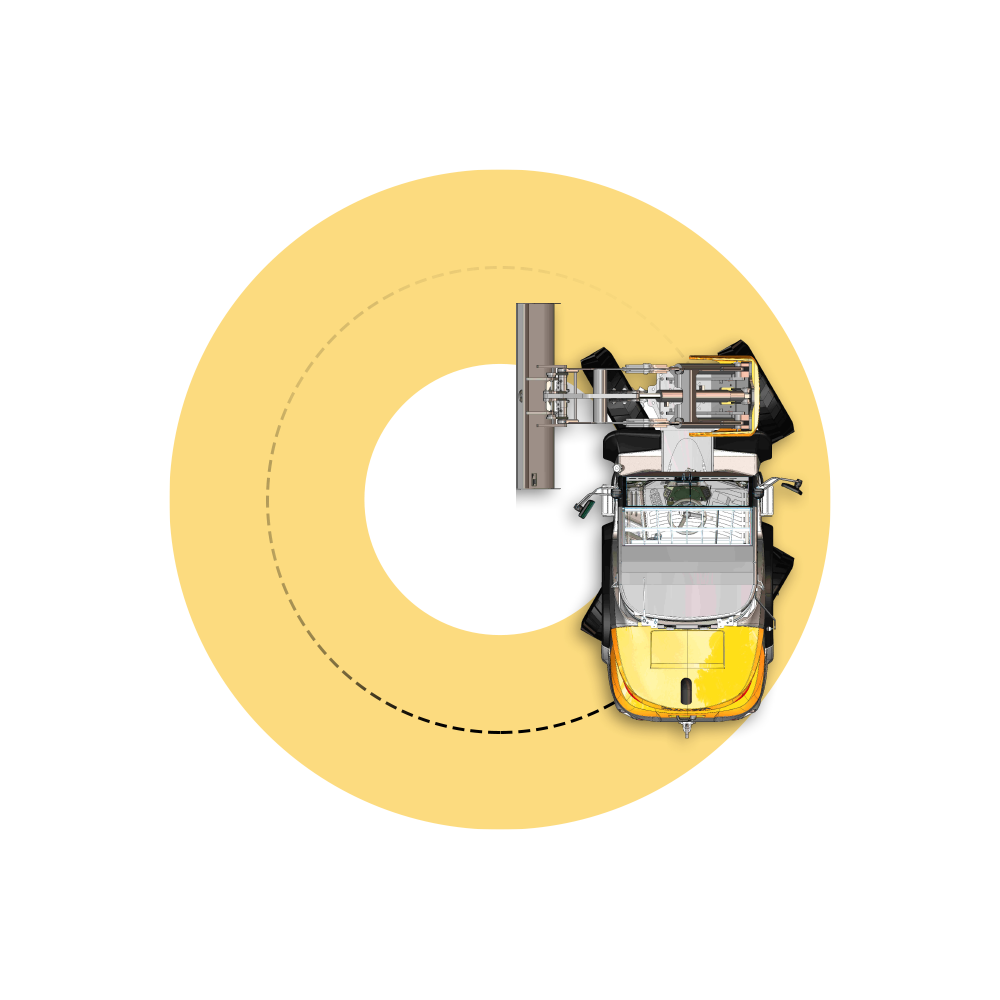

Turning radius over bucket

With its four-wheel steering and 180° swivel arm, the Mecalac swing can complete a full rotation in an area that is 20% smaller than that required by a conventional loader.

ARTICULATED LOADER

SWING LOADER

Swing Concept

Space management

Mecalac Swing: Immediate Efficiency

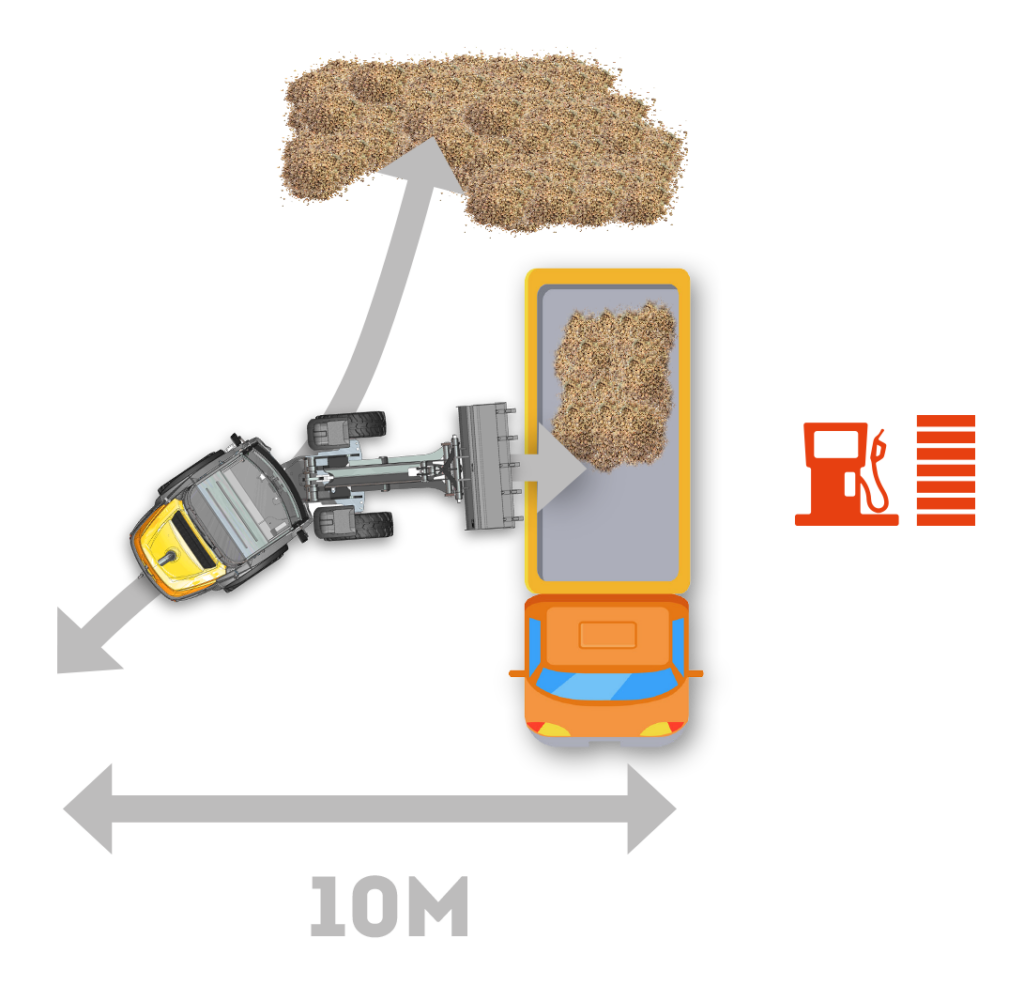

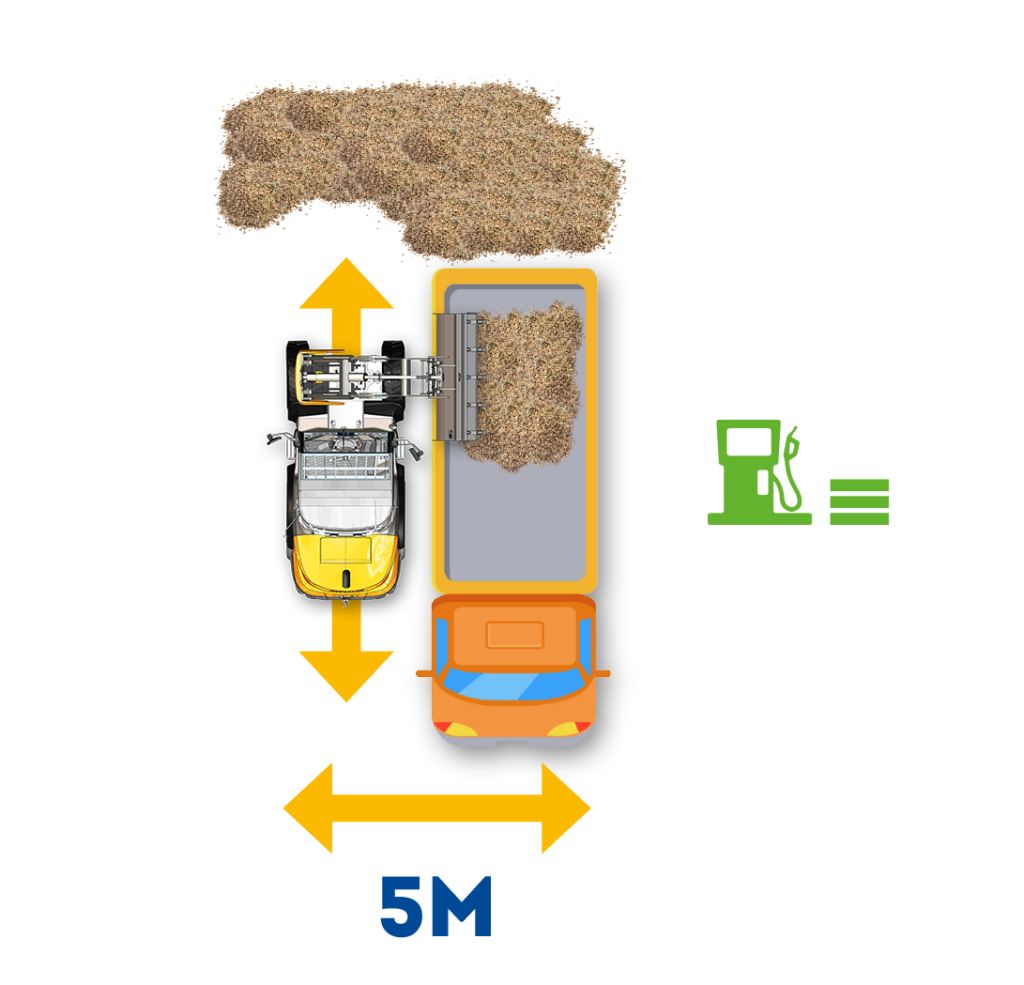

Swing loaders are particularly well-suited for work sites with limited space and time. Their compact design greatly enhances their efficiency, which is significantly impacted by the loading and unloading cycles. These cycles involve various time-consuming maneuvers that can constitute a large portion of a conventional loader’s working hours. To address this issue, the innovative Mecalac Swing Loader concept was developed. This swing design focuses on improving the operational aspects of a wheeled loader, thereby enhancing both its efficiency and the comfort of the operator.

ARTICULATED LOADER

SWING LOADER

Compactness, efficiency

Operational efficiency has significantly improved due to time savings during all manoeuvres and a reduction in unnecessary movements. The Swing Loader, which is equipped with an articulating arm, can pivot instead of requiring repositioning. This design leads to less wasted time, reduced noise and visual disturbances, lower maintenance requirements, decreased accident risk, and a smaller environmental impact. For instance, while a conventional loader requires a footprint of 10 meters to load a truck, the Swing Loader only needs 5 meters.

ARTICULATED LOADER

SWING LOADER

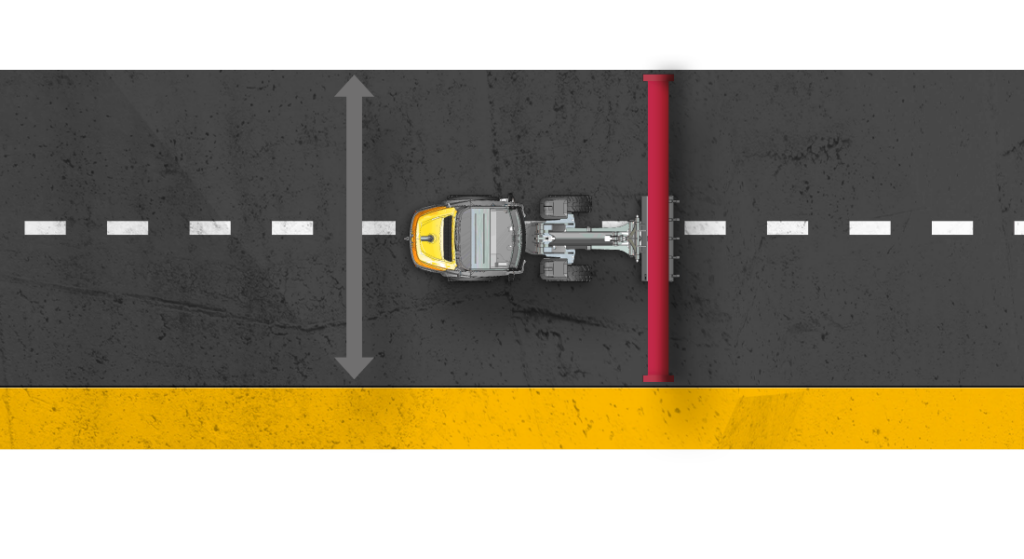

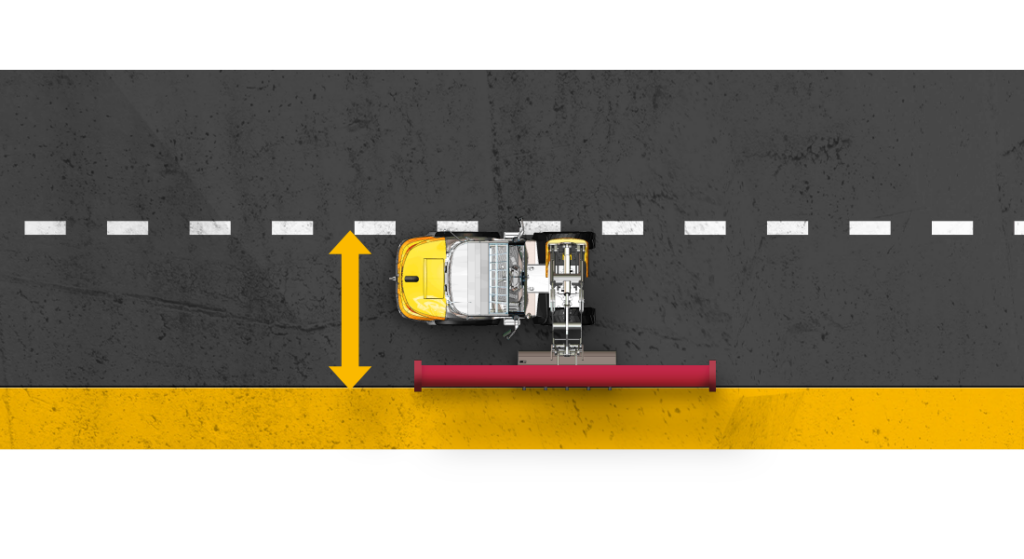

Sanding a trench

Not blocking traffic while filling a trench saves time and reduces disruption. The Mecalac Swing Loader’s remarkable compactness allows it to dump sand in a single lane, while other loaders typically require two lanes.

VIDEOS

Specifications

| Total operating weight | 7250 kg (15,983 lb) |

| Engine power | 55,4 kW (75 hp - 74.3 imperial hp) |

| Lift height / Loader | 4100 mm (13’5”) |

| Bucket volumes | 0,70 – 1,20 m³ (0.92 - 1.6 yd³) |

| Standard bucket volume | 0,70 m³ (0.92 yd³) |

| Lifting height with forks | 4720 mm (15’5”) |